Sportelli.tech

Specialist for 35 years in the work of tube, wire and profile, our team designs, realizes and develops any specific means of production for bending and endforming.

We have a wide standard range, adaptable to your specifications.

Our expertise also allows us to respond to tailor-made issues.

Complete control from the design to the delivery of your machine translates into premium quality and compliance with our commitments on time.

The reliability of our products guarantees production with complete peace of mind.

Our client’s activities

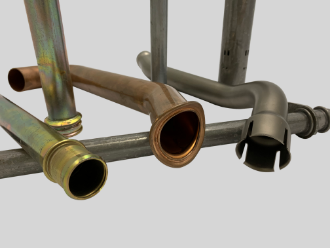

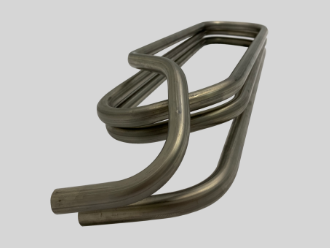

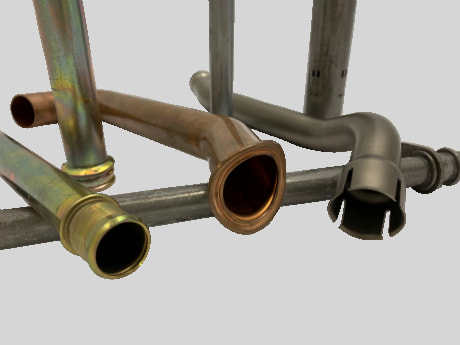

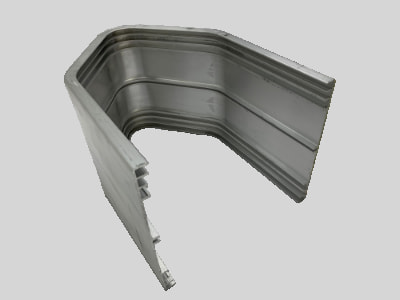

The versatility of our machines and tools allows us since 1985 to respond to different sectors of activity and this, for the work of all types of tube sections (round, square, rectangular, MCR …), all types of raw materials (steel, stainless steel, copper, aluminum, etc.).

Tool Machines

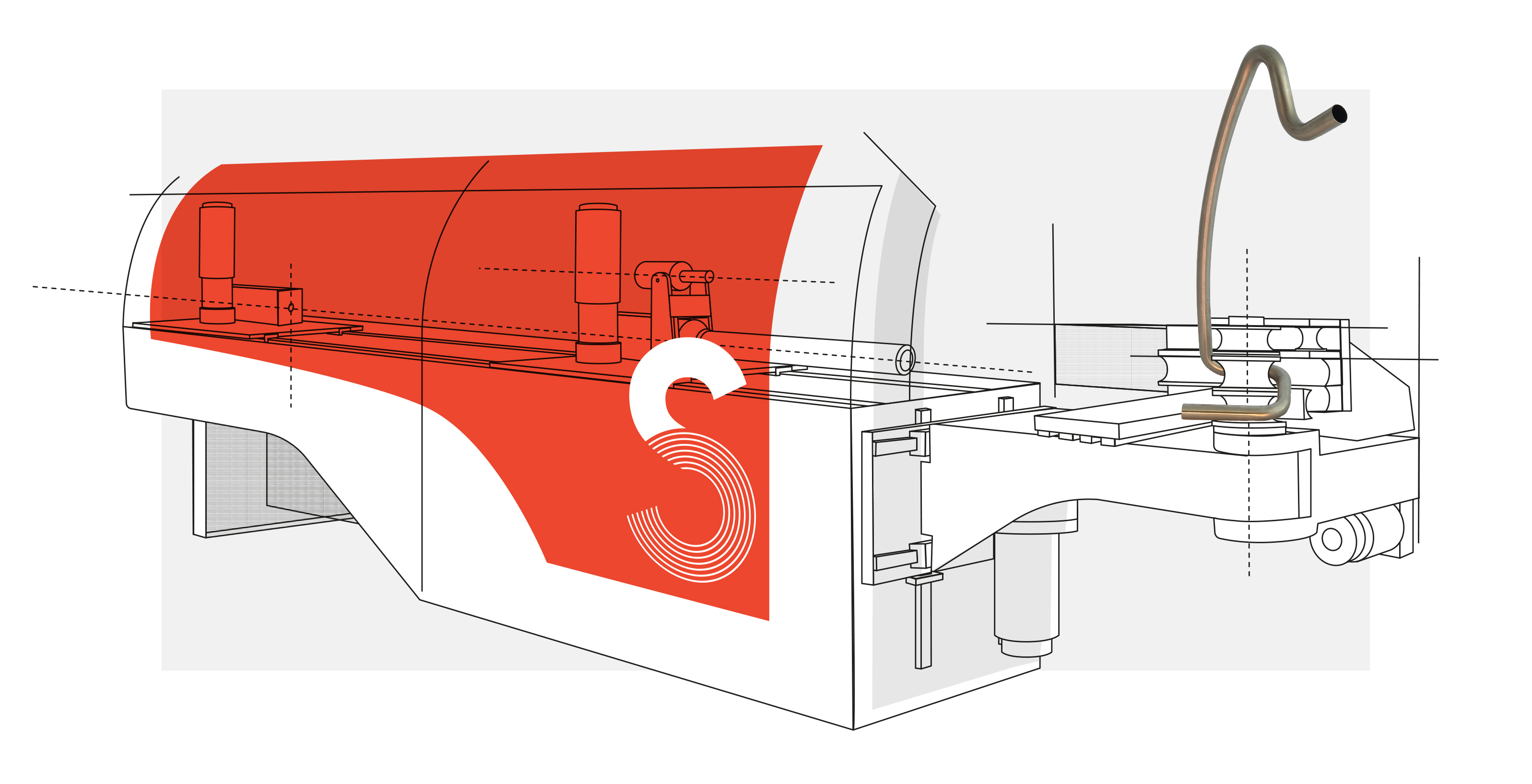

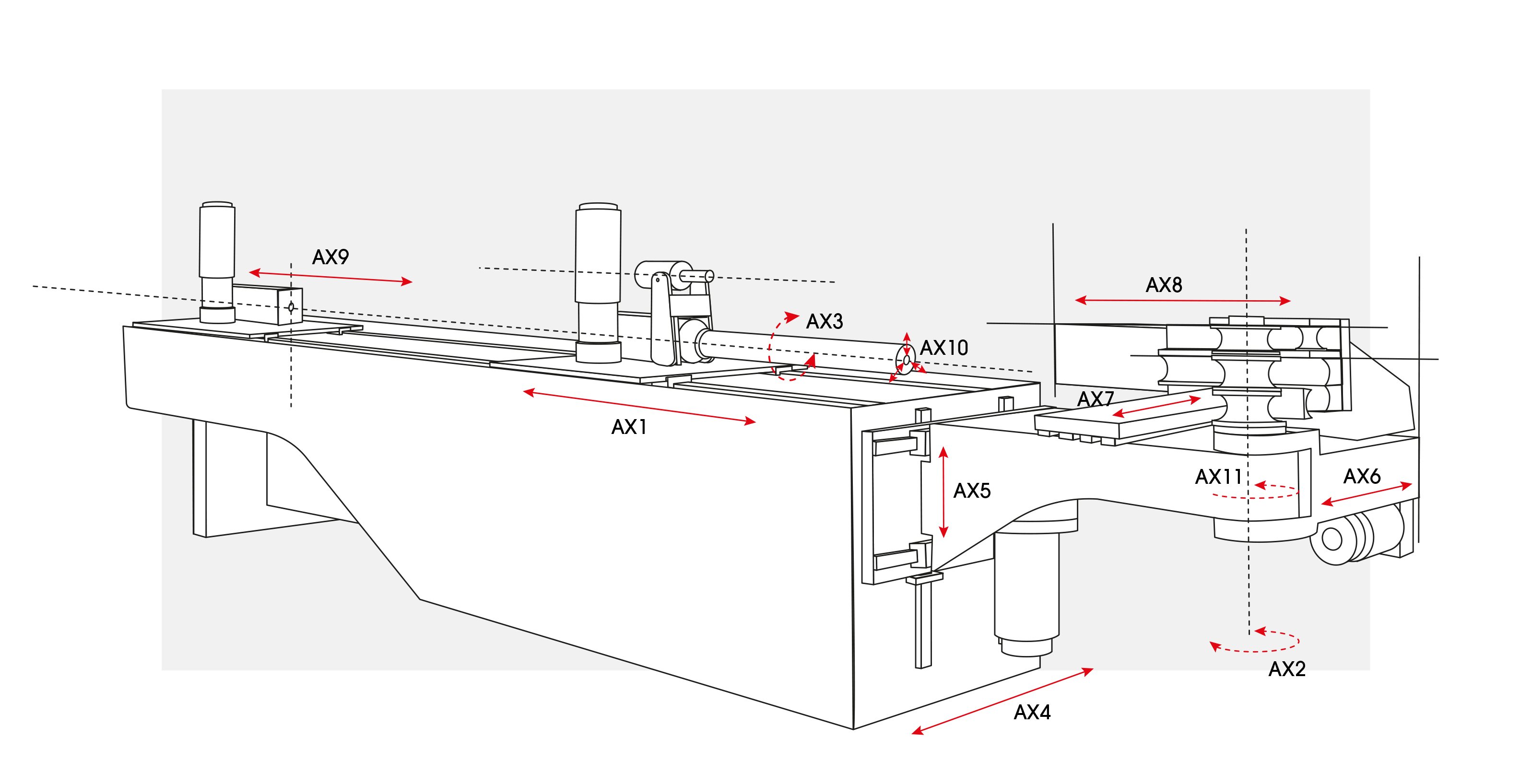

Sportelli.Tech offers a range of FANUC ALL-ELECTRIC BENDING AND / OR ROLLING MACHINES FROM 1 TO 11 FANUC AXES, available in 25, 45 and 65mm capacity (round steel tube).

Obvious advantages:

Implementation time reduced to the simplest.

Each movement is controlled by an electric axis and each tool setting program can be memorized. The absence of mechanical adjustment allows rapid configuration times and constant precision (no mechanical adjustment necessary).

Mini maintenance for maximum reliability: there is no need anymore to demonstrate the reliability of the entire FANUC pack delivered with our machines, the fruit of decades of use, from the field of robotics.

The machines remain clean, silent and require minimal energy consumption, and only when needed.

All our machines are controlled by programming software developed entirely in-house, which allows us greater responsiveness according to your specific needs. This ensures automatic programming by import of files (type .Iges / .Step, etc.), an automatic generation of the bending program, as well as a feasibility analysis by 3D simulation. And all this from your design office or directly on board of the machine.

And what about our connection to a three-dimensional measurement bench so that you can check and modify your bending program online according to any variations noted.

The loading and unloading of the tubes on our machines can be done either manually or automatically, by integrating them into the fully robotized islands.

We can complete the bending operations with finishing operations which go through end-forming to punching, crushing, cutting … In masked time.

Technical achievements

Contact us

Headquarters France

2 Rue Jacquard – 91280 Saint-Pierre-du-Perray

Tél. : +33 (0)1 69 891 891 | Mail : contact@sportelli.tech

Tube Tech Center Italia

Factory for the design and assembly of our tube bending and shaping machines

Via Piersanti Mattarella, 13/15 – 36061 Bassano del Grappa (VI)

Tel. : +39 (0)424 235004 | Mail : bdg@sportelli.tech

A3S Services

Technical service / After-sales service / spare parts / set-up / training

ZI Le Royeux – 4 Avenue de l’Europe – 02430 GAUCHY – France

Tél. : +33 (0) 3 23 65 12 12 | Mail : contact@a3s.services

A3S Mecanique

Mechanical parts and sub-assemblies, tools / Templates…

ZI Le Royeux – 4 Avenue de l’Europe – 02430 GAUCHY – France

TEL : +33 (0) 3 23 65 12 12 | Mail : contact@a3smecanique.fr

©Sportelli.tech - Copyright 2020

Mentions légales